3M vs BODAQ: Which Vinyl Wrap is Right for Your Kitchen?

When homeowners start researching cabinet wrapping, two brand names dominate the conversation: 3M DI-NOC and BODAQ Interior Film. Both are commercial-grade architectural vinyls. Both are used in high-end applications worldwide. So what's the difference, and which is right for your kitchen?

After installing thousands of square feet of both materials across Toronto kitchens, here's our honest comparison.

Table of Contents

- Quick Comparison: 3M vs BODAQ

- 3M DI-NOC: The Global Standard

- BODAQ Interior Film: The Premium Challenger

- Durability Comparison

- Finish Options and Patterns

- Heat and Moisture Resistance

- Installation Differences

- Pricing Comparison

- Which Should You Choose?

- Frequently Asked Questions

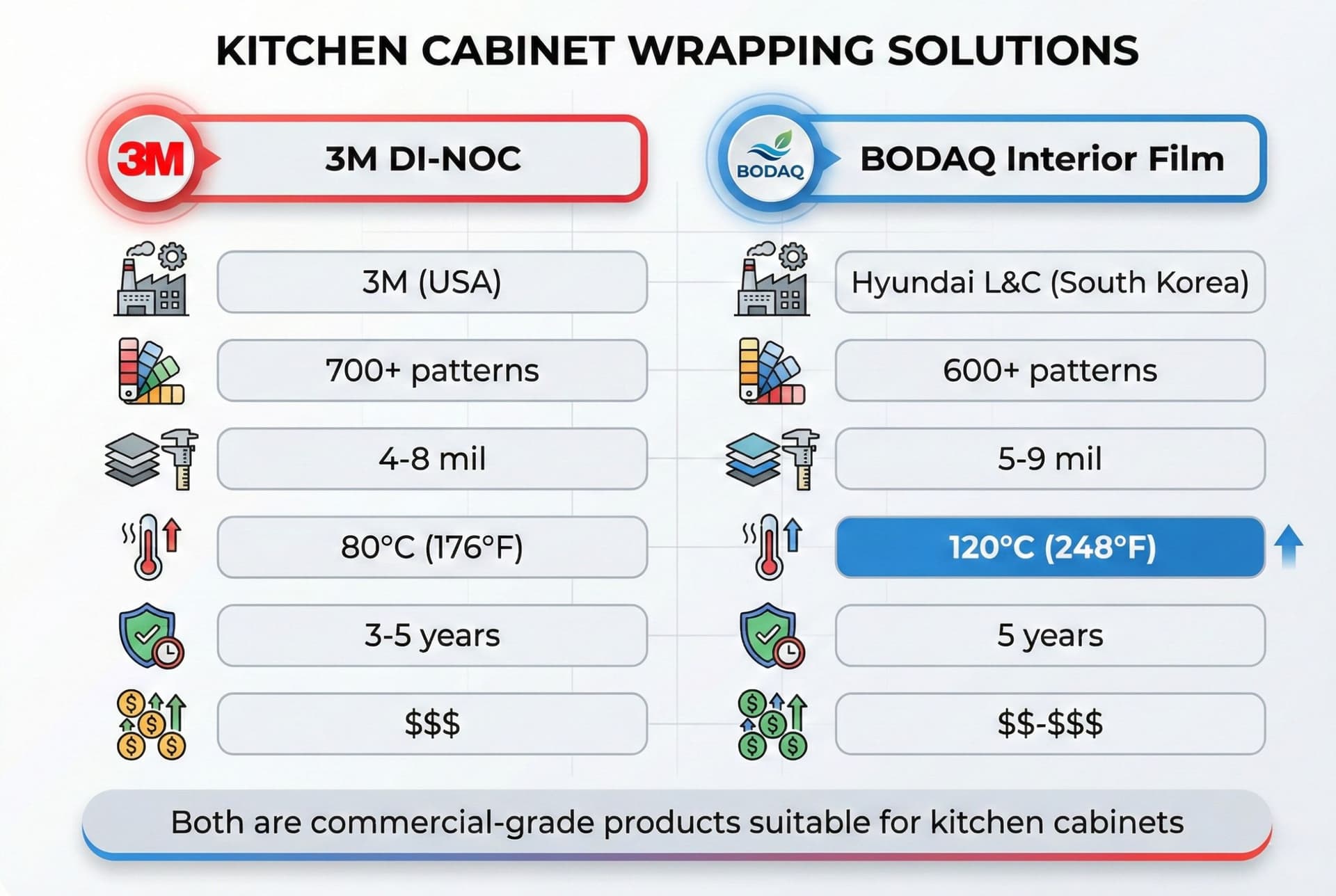

Quick Comparison: 3M vs BODAQ

| Factor | 3M DI-NOC | BODAQ Interior Film |

|---|---|---|

| Manufacturer | 3M (USA) | Hyundai L&C (South Korea) |

| Commercial Use | Hotels, offices, retail | Hotels, hospitals, transit |

| Pattern Library | 700+ patterns | 600+ patterns |

| Thickness | 4-8 mil | 5-9 mil |

| Heat Resistance | Up to 80°C (176°F) | Up to 120°C (248°F) |

| Warranty | 3-5 years (commercial) | 5 years (commercial) |

| Price Point | $$$ | $$ - $$$ |

| Best For | Traditional finishes, proven reliability | Modern finishes, areas near heat |

Bottom line: Both are excellent commercial-grade products. BODAQ offers better heat resistance and often lower pricing. 3M has broader brand recognition and a slightly larger pattern library.

3M DI-NOC: The Global Standard

3M has been producing architectural films for decades. Their DI-NOC product line is the industry benchmark — when architects specify vinyl finishes for commercial projects, 3M is often the default specification.

Strengths of 3M DI-NOC

Proven Track Record

3M DI-NOC has been installed in commercial buildings worldwide for 20+ years. You'll find it in hotels, airports, retail spaces, and healthcare facilities. This track record means thoroughly tested adhesive systems and reliable performance data.

Broad Pattern Selection

With 700+ patterns, 3M offers exceptional variety:

- Wood grains (oak, walnut, maple, teak, exotic species)

- Metal finishes (stainless steel, copper, brass, bronze)

- Abstract and geometric patterns

- Stone and marble effects

- Solid colors and textures

Consistent Quality Control

As a multinational corporation, 3M maintains rigorous quality standards across all manufacturing. Color consistency between batches is reliable, which matters for large projects or future touch-ups.

Widespread Availability

3M distributors are everywhere. If you need additional material or a specific color match, sourcing is straightforward.

Limitations of 3M DI-NOC

Price Premium

3M's brand recognition comes with premium pricing. For the same application, you'll often pay 15-25% more for 3M compared to equivalent BODAQ products.

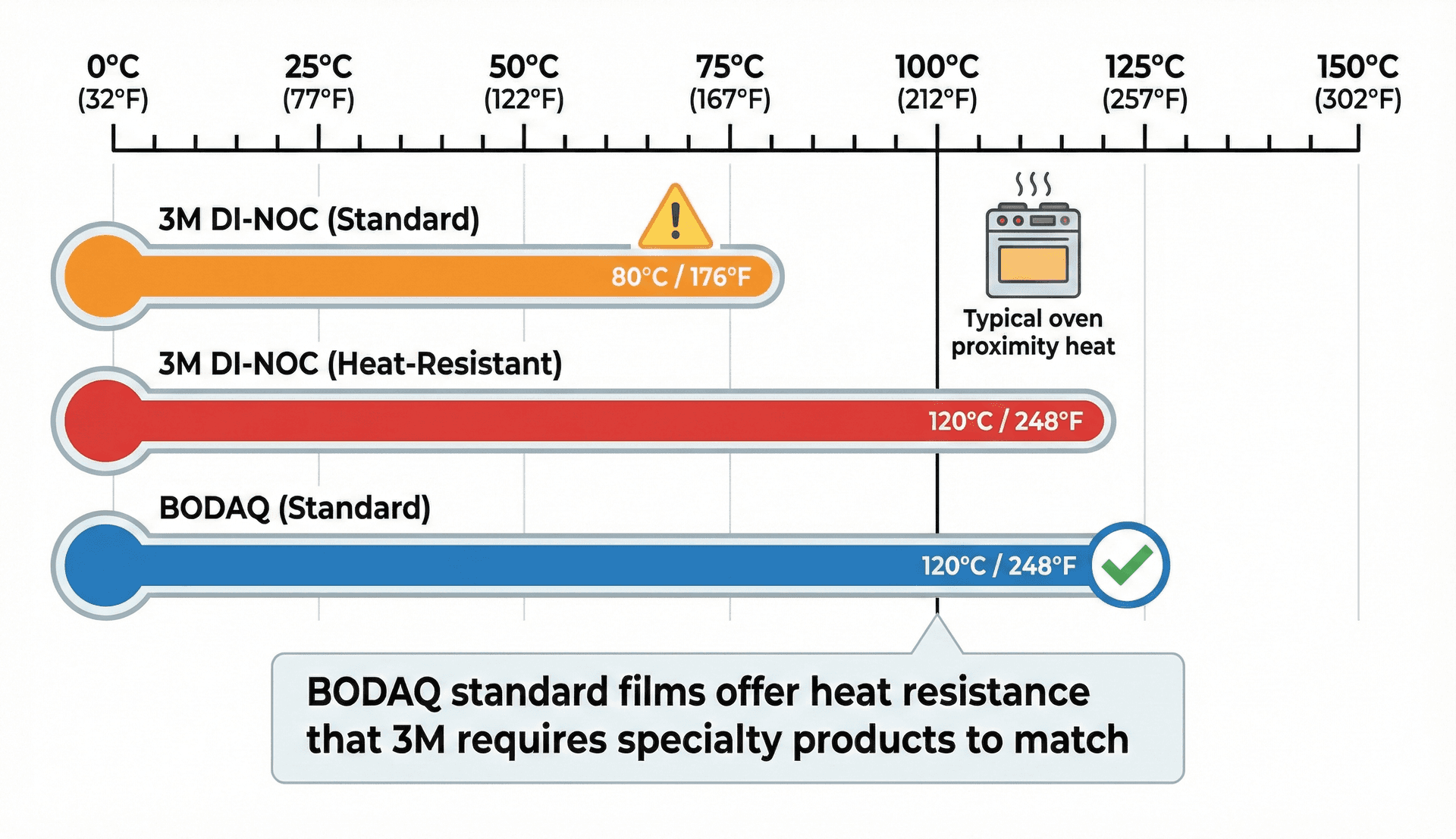

Heat Resistance

Standard DI-NOC is rated to 80°C (176°F). While fine for most cabinet applications, it's not ideal for cabinets directly adjacent to ovens without using their specialized heat-resistant variants.

Conservative Pattern Updates

3M's pattern library leans traditional. If you want cutting-edge finishes or contemporary designs, BODAQ often releases trendy patterns sooner.

BODAQ Interior Film: The Premium Challenger

BODAQ is manufactured by Hyundai L&C — the building materials division of Hyundai. Less familiar to North American consumers, but widely used in Asian commercial projects, transit systems, and healthcare facilities.

Strengths of BODAQ Interior Film

Superior Heat Resistance

BODAQ's standard films are rated to 120°C (248°F) — significantly higher than 3M's standard range. This makes BODAQ the safer choice for cabinets near ovens and dishwashers without needing specialized heat-resistant variants.

Thickness and Feel

BODAQ films tend to be slightly thicker (5-9 mil vs 4-8 mil for 3M). This provides:

- Better coverage over minor surface imperfections

- More substantial feel

- Improved durability in high-contact areas

Competitive Pricing

BODAQ typically costs 15-25% less than equivalent 3M products while delivering comparable (sometimes superior) performance. For budget-conscious projects, this matters.

Modern Finish Options

BODAQ's pattern library emphasizes contemporary design:

- Super-matte finishes that resist fingerprints

- Realistic concrete and industrial textures

- Modern wood grains (grey-washed, weathered looks)

- Trendy color palettes

Commercial Certifications

BODAQ carries serious certifications:

- TSSA approval (Ontario safety requirements)

- ASME A17.1 / CSA B44 compliance (elevator applications)

- ASTM E84 Class 1 fire rating

These certifications mean BODAQ meets stricter commercial requirements than residential applications demand.

Limitations of BODAQ

Smaller Pattern Library

With 600+ patterns vs 3M's 700+, BODAQ has slightly fewer options. In practice, both offer sufficient variety for virtually any design vision.

Less Brand Recognition

Some clients specifically request 3M based on name recognition. If brand matters for resale or documentation purposes, 3M may have an edge.

Sourcing in Remote Areas

BODAQ's distribution network is smaller than 3M's. In major markets like Toronto, this isn't an issue. In remote areas, sourcing can be slower.

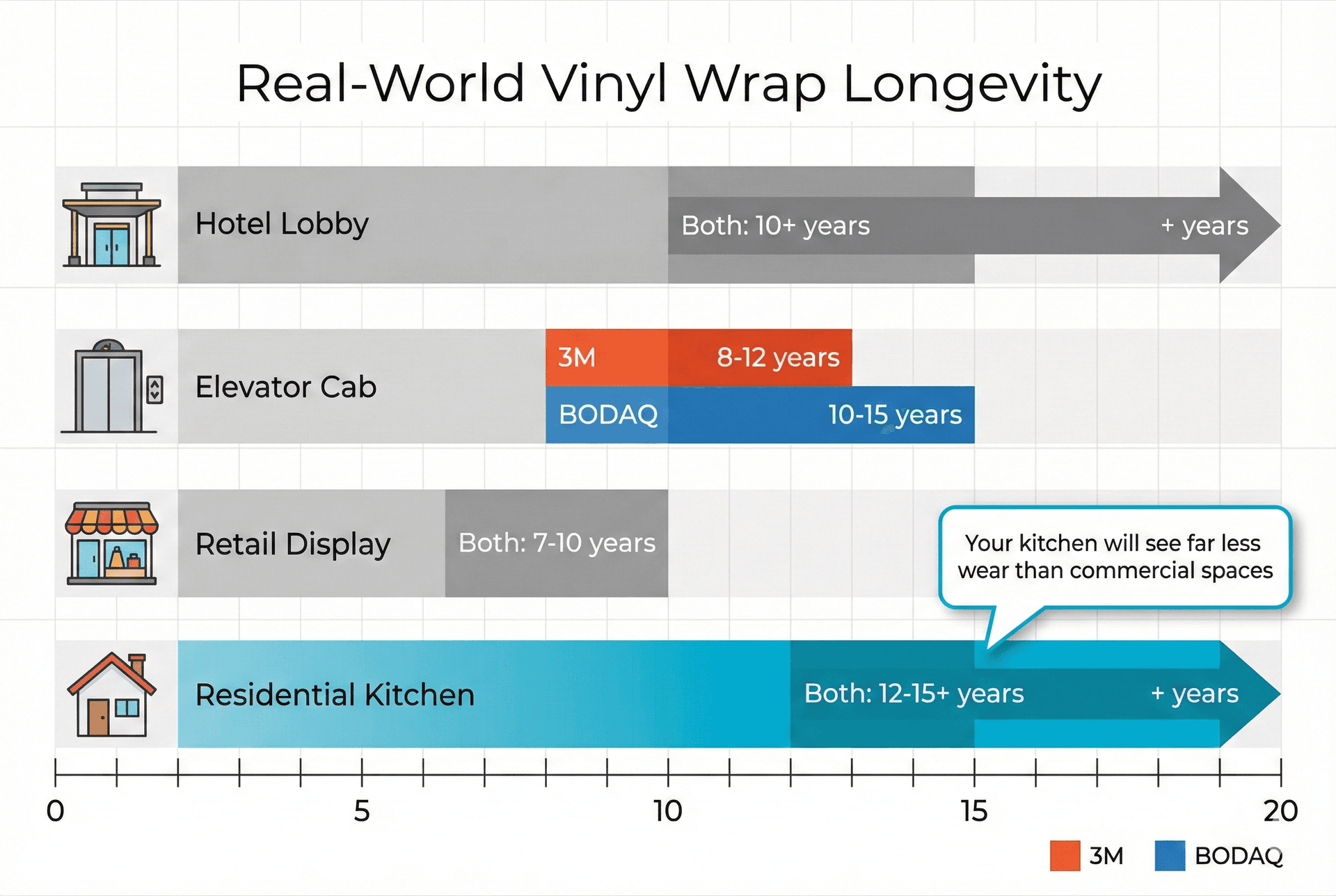

Durability Comparison

Both materials are engineered for commercial use — environments far more demanding than residential kitchens.

Real-World Longevity

| Environment | 3M DI-NOC | BODAQ |

|---|---|---|

| Hotel lobby (high traffic) | 10+ years | 10+ years |

| Elevator cab | 8-12 years | 10-15 years |

| Retail display | 7-10 years | 7-10 years |

| Residential kitchen | 12-15+ years | 12-15+ years |

In residential applications, both materials will outlast kitchen trends. You'll want to change your cabinets' look before either material fails.

Adhesive Systems

Both use commercial-grade pressure-sensitive adhesives with:

- High initial tack

- Long-term bond strength

- Resistance to humidity and temperature cycling

- Clean removability when eventually replaced

Neither will damage your underlying cabinet surfaces if properly removed.

Scratch and Wear Resistance

Both materials resist typical kitchen wear:

- Daily handling around handles and edges

- Cleaning with standard household products

- Minor impacts and scratches

BODAQ's slightly thicker construction may provide marginal advantages in heavy-use areas, but real-world difference is minimal.

Finish Options and Patterns

Wood Grain Finishes

| Style | 3M | BODAQ |

|---|---|---|

| Traditional oak | Excellent | Excellent |

| Walnut | Excellent | Excellent |

| Grey-washed/modern | Good | Excellent |

| Exotic species | Excellent | Good |

| Reclaimed/weathered | Good | Excellent |

Verdict: 3M edges ahead for traditional wood species. BODAQ excels at contemporary and weathered wood looks.

Metal Finishes

Both offer stainless steel, brushed metal, copper, and brass finishes. Quality is comparable — the difference is in specific color tones rather than overall quality.

Matte Finishes

This is where BODAQ particularly excels. Their super-matte finishes:

- Resist fingerprints better than 3M equivalents

- Maintain consistent appearance with daily use

- Offer deeper matte depth

For modern kitchens with matte cabinet goals, BODAQ is often the better choice.

Stone and Marble

Both offer marble, concrete, and stone patterns. 3M's library is slightly larger, but BODAQ's contemporary concrete and terrazzo options are particularly well-executed.

Heat and Moisture Resistance

Heat Resistance

| Product | Standard Rating | Near Oven Suitability |

|---|---|---|

| 3M DI-NOC (standard) | 80°C (176°F) | Caution required |

| 3M DI-NOC (heat-resistant) | 120°C (248°F) | Yes |

| BODAQ (standard) | 120°C (248°F) | Yes |

Key insight: BODAQ's standard films offer heat resistance that requires specialized 3M products to match. For kitchens with cabinets near ovens, BODAQ simplifies material selection.

Moisture Resistance

Both materials handle kitchen humidity well:

- Resistant to steam from cooking

- Washable with standard cleaners

- Won't delaminate from humidity cycling

Neither material should be submerged or used in direct water contact (not an issue for cabinet applications).

Installation Differences

From an installer's perspective, both materials work similarly:

Similarities

- Both use air-release adhesive technology

- Both conform well to edges and corners with heat

- Both require similar surface preparation

- Both use standard vinyl application techniques

Subtle Differences

BODAQ tends to be slightly more forgiving during installation due to its thickness. Minor surface imperfections show through less readily.

3M has marginally better repositioning capability during initial application — useful for precision alignment on pattern-matched installations.

For professional installers, both materials are straightforward. The differences don't significantly impact installation time or technique.

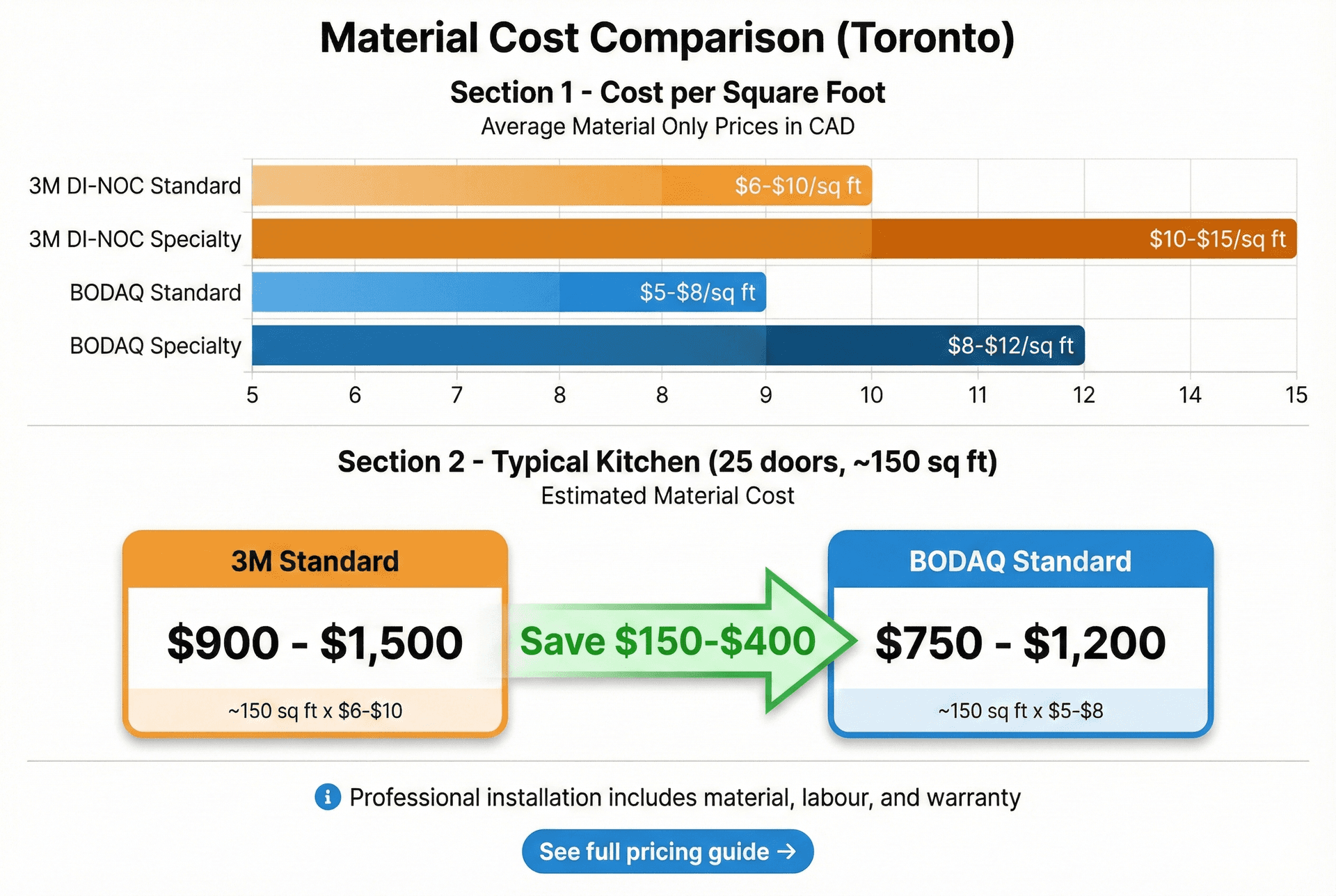

Pricing Comparison

Pricing varies by pattern and distributor, but general guidelines for Toronto:

| Product | Material Cost (per sq ft) |

|---|---|

| 3M DI-NOC (standard patterns) | $6 - $10 |

| 3M DI-NOC (specialty patterns) | $10 - $15 |

| BODAQ (standard patterns) | $5 - $8 |

| BODAQ (specialty patterns) | $8 - $12 |

For a typical 25-door kitchen requiring approximately 150 sq ft of material:

| Option | Material Cost |

|---|---|

| 3M standard | $900 - $1,500 |

| BODAQ standard | $750 - $1,200 |

The $150-400 difference in materials translates to meaningful savings on larger projects.

Note: Professional installation includes material, labour, and warranty. See our pricing guide for total project costs.

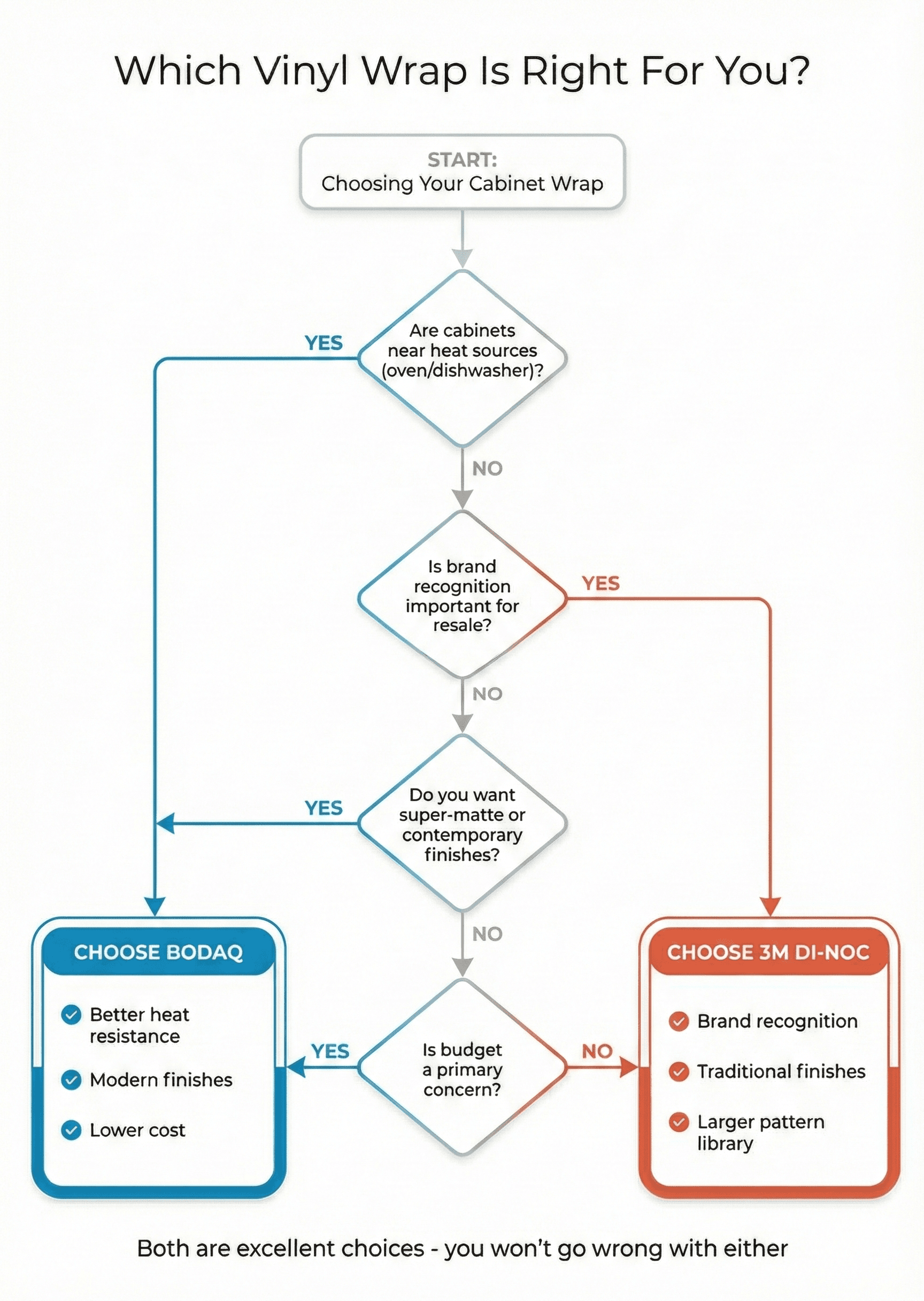

Which Should You Choose?

Choose 3M DI-NOC If:

- Brand recognition matters — for resale documentation or client specification

- You want traditional wood finishes — 3M's classic species selection is exceptional

- You need an exact color match — 3M's consistency and availability make matching easier

- Your installer prefers it — experienced installers often have brand preferences based on familiarity

Choose BODAQ If:

- Your cabinets are near heat sources — standard BODAQ handles heat better than standard 3M

- You want super-matte finishes — BODAQ's matte options are industry-leading

- Budget matters — BODAQ delivers comparable quality at lower material costs

- You prefer contemporary aesthetics — BODAQ's modern patterns align with current trends

- You want thicker, more substantial feel — BODAQ's construction is marginally more robust

Our Recommendation

For most Toronto kitchen projects, BODAQ Interior Film offers the best value:

- Superior heat resistance without specialty products

- Excellent contemporary finish options

- Lower material costs at comparable quality

- Strong commercial certifications

We use both materials depending on client preferences and project requirements. Both are excellent products — you won't go wrong with either.

Want to see samples? Request a free consultation and we'll bring pattern samples from both brands to your home.

Frequently Asked Questions

Is BODAQ as good as 3M?

Yes. BODAQ meets the same commercial standards as 3M and offers superior heat resistance in standard products. Both are used in demanding commercial applications worldwide. BODAQ is manufactured by Hyundai L&C, a major building materials company with rigorous quality standards.

Which vinyl wrap lasts longer on cabinets?

Both 3M and BODAQ last 10-15+ years in residential kitchens. In commercial applications, both perform for 8-12 years under heavy use. For practical purposes, durability is equivalent — other factors should drive your choice.

Does BODAQ work near kitchen ovens?

Yes. BODAQ's standard films are rated to 120°C (248°F), making them suitable for cabinets adjacent to ovens and dishwashers without needing specialized heat-resistant variants. This is one of BODAQ's key advantages.

What warranty comes with cabinet wrapping?

Material warranties are typically 3-5 years from both manufacturers. Professional installation warranties vary by company — we offer a 5-year warranty covering both materials and workmanship.

Can I get samples of both materials?

Yes. During our free consultation, we bring samples from both brands so you can compare patterns, textures, and finishes in your kitchen's lighting.

Which is better for matte white cabinets?

BODAQ's super-matte finishes are generally superior for achieving the true matte look popular in modern kitchens. Their matte finishes also resist fingerprints better than 3M's matte options.

Is one easier to remove than the other?

Both use adhesive systems designed for clean removal. When properly removed with heat, neither damages underlying surfaces. Removal characteristics are essentially equivalent.

Ready to transform your kitchen? We install both 3M and BODAQ films across Toronto, Mississauga, Vaughan, Oakville, Markham, Richmond Hill, and the entire GTA. Get your free quote.

Related Reading

- Cabinet Wrapping vs Painting: Which Is Better? — Complete comparison guide

- DIY Cabinet Wrapping vs Professional Installation — What to consider before DIYing

- Can You Wrap Thermofoil Cabinets? — Special considerations for thermofoil

- Kitchen Cabinet Wrapping Services — Our full cabinet wrapping service

- Interior Door Vinyl Wrapping — Extend the transformation to your doors

- Cabinet Wrapping Cost Guide — Detailed Toronto pricing

Ready to Transform Your Kitchen?

Get an instant quote for your cabinet wrapping project. Upload photos and see your price in 60 seconds.

Get Your Free Quote